A continuación se presentan algunas características y consideraciones clave con respecto a los resortes de compresión de alta resistencia.:

1. Capacidad de carga:

Los resortes de compresión de alta resistencia están diseñados específicamente para soportar cargas o fuerzas sustanciales.. Están hechos de materiales con alta resistencia a la tracción y están fabricados para soportar las importantes fuerzas de compresión que encontrarán..

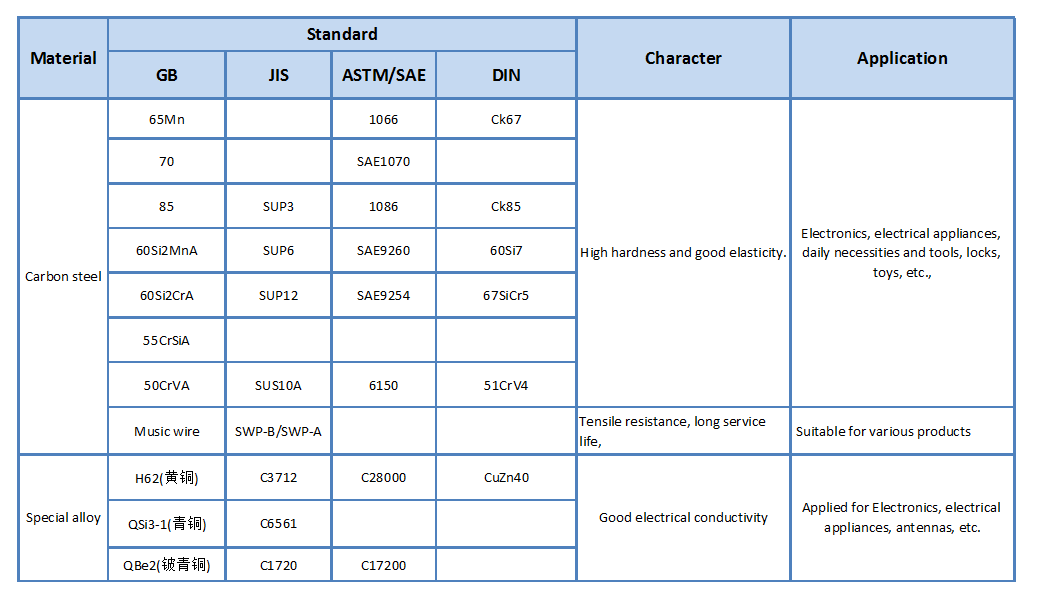

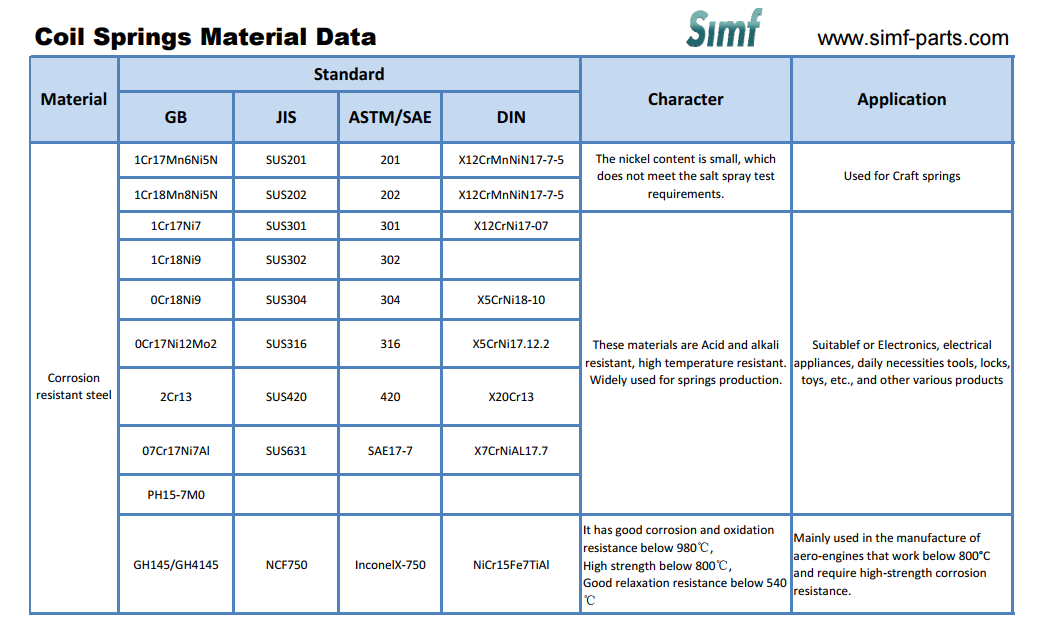

2. Selección de materiales para resortes de compresión de alta resistencia:

Los resortes utilizados para aplicaciones de servicio pesado generalmente están hechos de materiales con excelentes propiedades mecánicas., como aceros aleados, aceros con alto contenido de carbono, y a veces aceros inoxidables. Estos materiales proporcionan la resistencia y durabilidad necesarias para soportar cargas pesadas y resistir la fatiga..

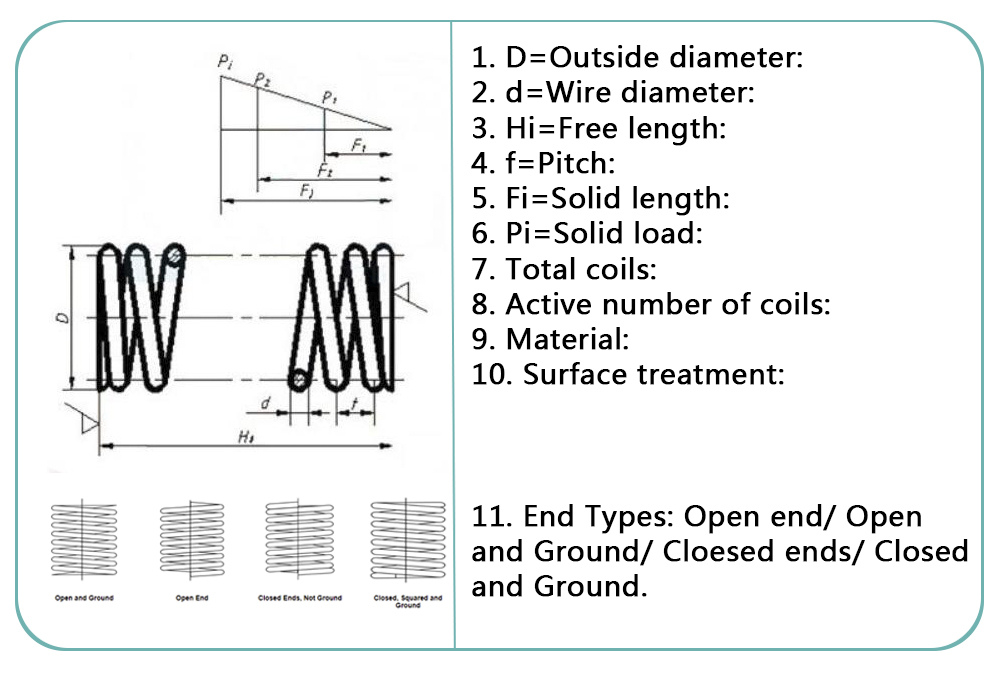

3. Diseño de bobina:

Las espiras de los resortes de compresión de alta resistencia suelen estar muy espaciadas, haciéndolos más resistentes al pandeo y ofreciendo mayor estabilidad bajo compresión. El diseño de las espiras también influye en la determinación de las características generales del resorte., como la tasa de primavera (la relación entre fuerza y desplazamiento) y distancia máxima de compresión.

4. Revestimiento y resistencia a la corrosión:

Dependiendo del entorno de la aplicación, Los resortes de compresión de alta resistencia pueden recubrirse o tratarse para mejorar su resistencia a la corrosión.. Esto es especialmente importante en entornos industriales donde la exposición a la humedad, quimicos, u otras sustancias corrosivas es común.

5. Personalización:

Los resortes de compresión de alta resistencia se pueden personalizar para adaptarse a requisitos específicos.. Esto incluye variaciones en el diámetro del alambre., diámetro de la bobina, número de bobinas, y el tipo de extremos (extremos cerrados, extremos abiertos, o diferentes tipos de extremos de fijación).

6. Durabilidad y longevidad:

Estos resortes están diseñados para tener una vida útil más larga y soportar ciclos de compresión repetidos sin una pérdida significativa de rendimiento.. El diseño y la selección de materiales adecuados son factores críticos para lograr esta durabilidad..

7. Consideraciones de seguridad:

Dado el potencial de altas cargas y fuerzas, La seguridad es una preocupación crucial al diseñar y utilizar resortes de compresión de alta resistencia.. Asegurarse de que los resortes tengan el tamaño adecuado, instalado, y mantenido es esencial para prevenir accidentes o fallas.

8. Ejemplos de aplicación:

Los resortes de compresión de alta resistencia se encuentran en diversas industrias., incluyendo equipos de construcción, maquinaria minera, maquinaria agrícola, aplicaciones aeroespaciales, maquinaria industrial a gran escala, y más.

Al diseñar o seleccionar resortes de compresión de alta resistencia, Es importante colaborar con expertos que tengan experiencia en diseño e ingeniería de resortes.. Factores como los requisitos de carga., limitaciones de espacio, y las condiciones ambientales influirán en el proceso de diseño y selección de materiales para garantizar que los resortes funcionen de manera confiable y segura en sus aplicaciones previstas..

Si quieres saber más sobre nuestra empresa, Puedes echar un vistazo a los siguientes vídeos..

>>>>Quienes somos?

>>>>Nuestro paquete.

>>>>Nuestra inspección.

>>>>Nuestra gente:

No puedo encontrar el resorte de disco que busca?

Solicite una cotización para un resorte personalizado hecho según sus especificaciones.