Wave spring

Wave springs, commonly referred to as waveform springs, are annular elastic components formed from thin metal rings through specialized manufacturing processes. Their structural feature involves uniformly distributing multiple peaks and valleys along the ring, enabling elastic deformation through axial relative displacement between these peaks and valleys. Waveform springs are extensively utilized in aerospace, automotive, precision machinery, hydraulic sealing, and high-end motor applications, primarily serving to reduce noise and vibration.

Characteristics

Type: Single-layer open/lap springs, opposing springs, continuously wound stacked springs, single-layer closed springs

Standards: JB/T 7590-2005, HG/T 2479-2003

Surface Treatment: Bluing, Phosphating, Electroplating, Electrophoresis

Common materials: 60Si2MnA, 50CrVA, stainless steel (such as SUS304, SUS316) and high-temperature resistant nickel-based alloys (such as Inconel718, Inconel750)

Classification

Wave springs can be primarily categorized based on their structural characteristics as follows:

1. Single-layer Springs

Single-layer springs can be further subdivided into the following types based on their end configurations:

· Single-layer closed-end wave springs: Featuring an “O”-shaped structure, these springs ensure better contact between wave peaks and troughs during compression, providing more uniform elastic force. · Single-layer open-end wave springs: Featuring a “C”-shaped structure, these springs prevent overlapping of the ends during compression, making them suitable for applications requiring greater deformation.

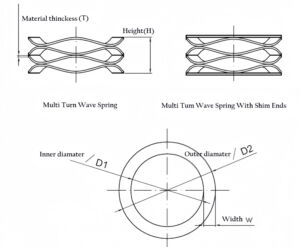

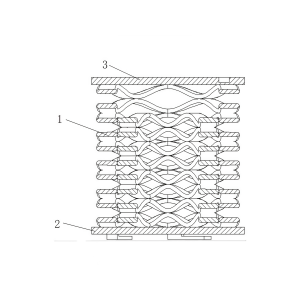

2. Multi-layer Springs

Multi-layer springs are primarily classified into the following two types based on their stacking method:

Multi-layer Peak-to-Peak (Series) Springs: Their spring force is inversely proportional to the number of coils. Suitable for applications requiring large displacement and medium to low spring force, they serve as an alternative to cylindrical springs.

Multi-layer peak-to-peak (nested) wave springs: Their spring force is proportional to the number of coils. While generating substantial force, they maintain the precise characteristics of wave springs. Suitable for applications requiring high spring force, they can replace disc springs.

If you want to know more about our company, you can take a view of the following videos.

>>>Who we are?

>>>>Our product.

>>>>Our Inspection.

>>>>Our people.