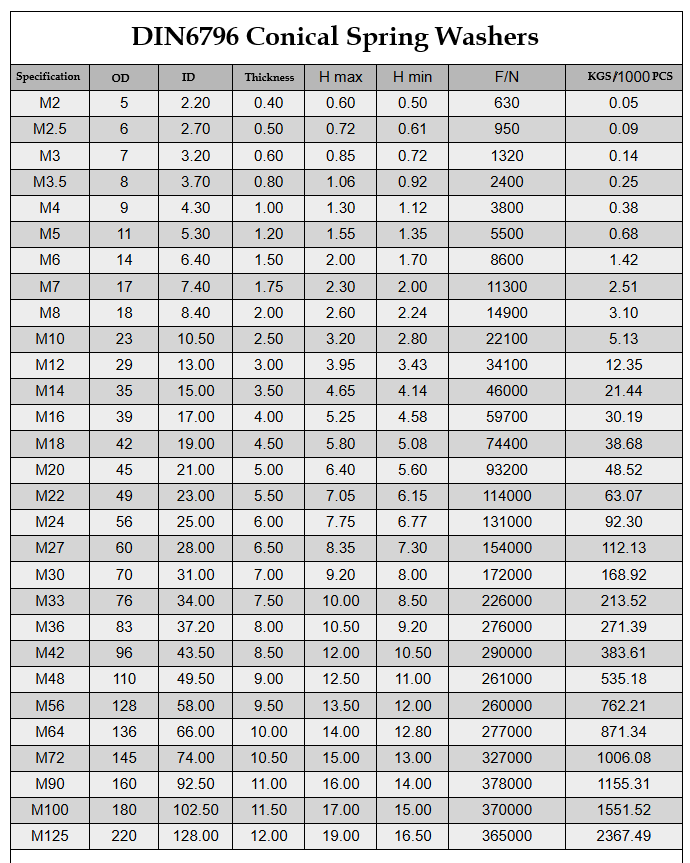

DIN 6796 Belleville Washers

Specification for DIN 6796 Belleville Washers

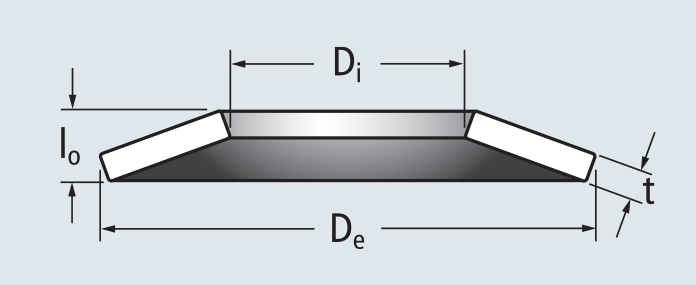

Our DIN 6796 belleville washers are produced according to the standard DIN6796, the standard specifies that the product’s outer diameter range is 6–250 mm, inner diameter 3.2–127 mm, and thickness 0.3–16 mm, suitable for M4 to M30 bolt connections.

Learn more about Belleville spring washers’ Specifications

Material for DIN 6796 Belleville Washers

Spring steel 60Si2Mn、65Mn、50CrVA, Stainless steel 304, stainless steel 316, Inconel X-750

We also manufacture from special materials.

Corrosion Protective for DIN 6796 Belleville Washers

Electrophoresis: Electrophoresis processing involves surface treatment of disc-shaped spring washers to remove obstacles between the coating film and the coated part surface, eliminating factors that affect their adhesion, such as oil stains, rust stains, oxide scale, and other impurities, thereby providing optimal conditions for electrophoresis coating.

Phosphating: Typically used for the surface treatment of carbon steel disc-shaped spring washers, this method achieves excellent surface finish by reacting with phosphoric acid or phosphates to form a stable phosphoric acid salt layer on the disc spring surface.

Electroplating: A surface treatment technology that uses electrolysis to deposit metal or alloy onto the surface of disc-shaped spring washers, forming a metal coating. Common electroplating processes for disc-shaped spring washers include zinc plating and nickel plating.

Dacromet: Also known as zinc-chromium coating, it is the transliteration and abbreviation of DACROMET. Compared to traditional electroplating, it is an “eco-friendly electroplating” method, featuring exceptional corrosion resistance, no hydrogen embrittlement, high heat resistance, and no pollution.

Application for DIN 6796 Belleville Washers

DIN6796 Conical Spring Washers are widely used in:

Aviation industry: used in high-strength fastening systems

Automobile manufacturing: used in engine and transmission component connections

Medical equipment: used in precision instrument shock absorption devices

Chemical machinery: used in anti-loosening fastenings in corrosive environments

Installation and Use

Installation Method: The ideal installation method is to flatten the washer as much as possible. The closer it is to a flattened state, the faster the tension torque increases, thereby achieving the appropriate bolt tension. Installation can be completed without a torque wrench.

If you want to know more about our company, you can take a view of the following videos.

>>>>Who we are?

>>>>Our production line?

>>>>Our package.

>>>>Our Inspection.

>>>>Our people: