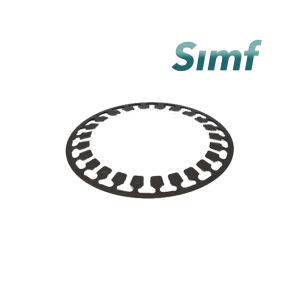

SIMFLEX Corrosion-resistant disc springs are made according to the standard DIN2093.

Outside diameter sizes range from 6.0mm to 90mm.

Learn more about Corrosion Resistant Disc Spring Specifications

Here are some key points about corrosion-resistant disc springs:

1. Material Selection:

Corrosion-resistant disc springs are typically made from stainless steel or other corrosion-resistant alloys. Stainless steel grades like 316 or 17-7 PH are commonly used due to their excellent corrosion resistance properties.

2. Corrosion Resistance:

These springs are designed to resist rust, oxidation, and other forms of corrosion that can degrade the mechanical properties of the spring. This makes them suitable for use in outdoor, marine, chemical, and other corrosive environments.

3. Load Distribution:

Corrosion-resistant disc springs are used in a wide range of applications, including marine equipment, offshore structures, chemical processing equipment, automotive components, pumps, valves, and other machinery operating in corrosive environments.

4. Applications:

Corrosion-resistant disc springs are used in a wide range of applications, including marine equipment, offshore structures, chemical processing equipment, automotive components, pumps, valves, and other machinery operating in corrosive environments.

5. Installation Considerations:

Proper installation practices are essential to ensure that the disc springs function as intended. Over-compression or under-compression of the springs can affect their performance and longevity.

6. Customization:

Corrosion-resistant disc springs can be manufactured in various sizes and configurations to suit specific application requirements.

When selecting corrosion-resistant disc springs, it’s important to consider factors such as the expected environment, the level of corrosion resistance needed, the required load capacity, and the specific deflection characteristics required for your application. Consulting with spring engineering experts can help ensure that the chosen springs are well-suited for the intended application and will perform reliably in corrosive conditions.

If you want to know more about our company, you can take a view of the following videos.

>>>>Who we are?

>>>>Our production line?

>>>>Our package.

>>>>Our Inspection.

>>>>Our people:

Can’t Find the Disc Spring You Are Looking For?

Request a quote for a custom spring made to your specifications.