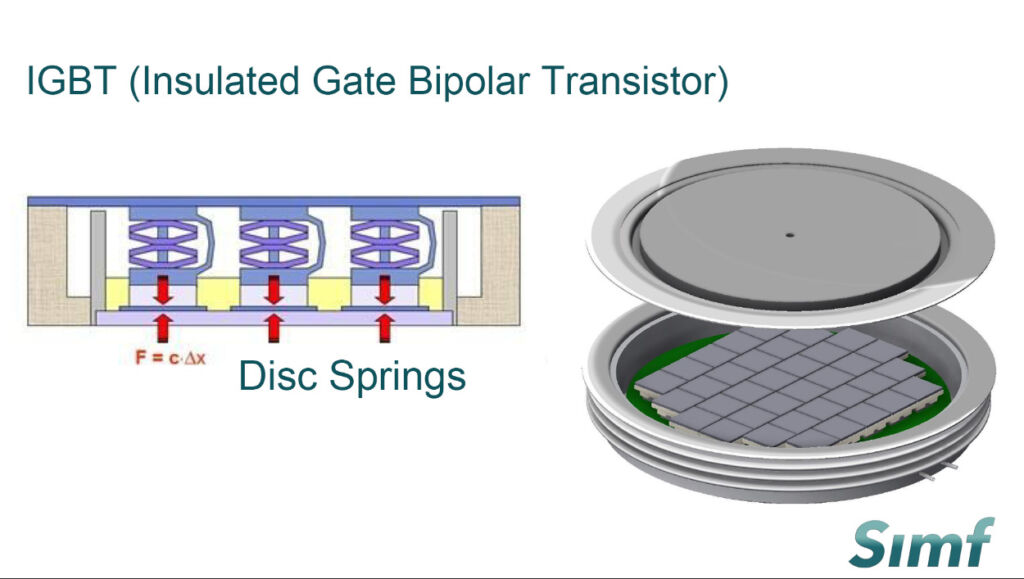

IGBT (Insulated Gate Bipolar Transistor) modules often utilize disc springs for thermal management and electrical isolation purposes.

These disc springs, also known as Belleville washers, are typically made of metal and are stacked together in a series.

In IGBT modules, disc springs are primarily used for:

Pressure Distribution: They help distribute pressure evenly across the module’s surface, ensuring proper contact between the semiconductor chips, baseplate, and cooling system. This is crucial for efficient heat dissipation.

Thermal Management: By applying pressure, disc springs help improve the thermal contact between the IGBT chips and the heatsink. This reduces thermal resistance and enhances the heat transfer from the chips to the cooling system, thus improving overall thermal performance.

Electrical Isolation: In some designs, the disc springs also provide electrical isolation between the power semiconductor devices and the heatsink or baseplate, preventing electrical contact and potential short circuits.

Overall, disc springs play a vital role in enhancing the reliability and performance of IGBT modules by ensuring proper thermal management and electrical isolation.